TAKEAWAY: Despite regulations that protect workers from overexposure to airborne silica, there are still situations in which it can be present in the air. Employers and workers need to be aware of potential exposure signs. Read on to learn about eight signs indicating you might have a problem with airborne silica on your job site.

Airborne silica is a serious concern for employees in construction, mining, and other industries where workers can inhale this potentially hazardous material. Inhalation of silica particles can lead to severe health problems such as pulmonary fibrosis, lung cancer, and even death.

Jump Ahead

What is Silica Dust?

Crystalline silica is a naturally occurring material found in many construction materials, such as concrete. In its natural form, it’s generally not harmful. When broken into smaller particles, inhaling the resulting dust can be dangerous. Silica dust particles can remain suspended in the air for several hours, posing a severe health risk to workers.

The Hazards of Airborne Silica

Inhaling crystalline silica dust can lead to long-term health complications, including chronic silicosis, pulmonary diseases, and lung cancer. These health risks are especially high in individuals exposed to high levels of silica dust for an extended period.

Contact us for all of your lung health testing requirements, such as respirator-fit testing, spirometry testing, and lung health monitoring programs.

Signs You May Have a Problem With Airborne Silica on Your Job Site

Given the widespread exposure to silica dust and its adverse health effects, employers must understand the warning signs and symptoms associated with airborne silica exposure and take necessary precautions for prevention.

- Workers Partake in Tasks that Produce Silica Dust

The first indication you may have a problem with airborne silica on your job site is the materials your workers use and associated job tasks.

For example, stone products, manufactured timber, cement, asphalt, bricks, and mortar, are examples of silica-containing materials.

Several activities can release airborne silica, including:

- Clay and stone processing and cutting

- Paving and surfacing

- Excavation, earth moving, and drilling plant operations

- Demolition and construction labouring

And there are many more. Employers should understand which activities using silica-containing materials could result in elevated levels of airborne silica, thus putting workers at risk of overexposure. Industries with the highest risk levels include construction, mining, masonry, and oil and gas.

The problem with looking for signs of silica in the workplace is that the particles are typically too small to see with the naked eye. Testing is the only accurate way to determine airborne silica level problems.

- Testing Shows Elevated Silica Levels

It’s essential to accurately test the levels of silica present in the air to protect employees from silica dust. Testing involves a sampling pump collecting air samples over a work shift.

These samples are analyzed in a laboratory, and the results are compared against the permissible exposure limit established by the Occupational Safety and Health Administration (OSHA).

Testing results outside permissible limits indicate you have a problem with airborne silica exposure on your job site.

Employee Signs and Symptoms

When working in an environment with airborne silica, employees should be aware of changes to their respiratory health. If a worker experiences respiratory symptoms, they should seek medical advice as soon as possible. Early detection and treatment can significantly reduce the potential for adverse health effects.

The remainder of the signs to watch for are related to employee symptoms.

- Shortness of Breath

Workers on job sites with airborne silica exposure may experience shortness of breath. Inhaling silica dust can cause lung damage, leading to shortness of breath.

It’s essential to note shortness of breath may also have other causes on the job site. Physical exertion or exposure to hazardous gases, such as carbon monoxide, can also lead to shortness of breath.

However, if shortness of breath is accompanied by other symptoms of lung damage, such as coughing or wheezing, it’s crucial to consider airborne silica exposure as a potential cause.

- Coughing or Wheezing

Coughing and wheezing are common symptoms of respiratory illnesses caused by exposure to airborne silica dust. When inhaled, silica dust particles can cause damage to the lungs, leading to chronic obstructive pulmonary disease (COPD). COPD can cause coughing and wheezing due to the narrowing of airways and obstruction of airflow.

- Chest Pain or Tightness

Silica particles can irritate the lung tissue and cause inflammation, resulting in chest pain or tightness. This symptom may not be immediately apparent but can develop over time, especially with repeated exposure to silica dust.

- Fatigue and Weakness

Airborne silica exposure can severely affect workers’ health, including chronic conditions leading to fatigue and weakness. Workers who experience shortness of breath, chest pain, and coughing or wheezing are likely to experience fatigue and weakness as they struggle to perform their tasks while coping with these symptoms. As the lungs become increasingly damaged, it becomes harder for workers to breathe, leading to fatigue and weakness due to a lack of oxygen.

- Reduced Lung Capacity

Reduced lung capacity is a typical result of exposure to airborne silica. Silica dust can enter the lungs and form scar tissue, causing lung tissue to become stiff and less elastic, ultimately leading to reduced lung capacity.

Symptoms associated with reduced lung capacity due to silica exposure include shortness of breath, coughing, chest pain, and wheezing.

- Chronic Obstructive Pulmonary Disease (COPD)

Exposure to airborne silica dust can increase the risk of developing COPD. COPD is a chronic condition that affects the lungs and causes reduced airflow, making it difficult for a person to breathe. Once someone has COPD, it’s an irreversible condition. However, it can be managed with medication, pulmonary rehabilitation, and lifestyle changes.

Bronchitis and emphysema are two examples of COPD diseases. When people inhale silica dust, it can cause lung scarring, leading to chronic bronchitis and emphysema.

Chronic bronchitis occurs when the bronchial tubes become inflamed and produce mucus, leading to persistent coughing. Emphysema results from damage and loss of elasticity in the air sacs in the lungs, reducing the amount of oxygen absorbed into the bloodstream.

Symptoms of airborne silica exposure may not be immediately apparent and could take years or even decades to manifest themselves. These symptoms could lead to severe and life-threatening illnesses if left untreated.

Controlling Airborne Silica

Employers and workers must take preventive measures to reduce exposure to silica dust and minimize the risk of respiratory illnesses. Best practices include:

- Wet methods for dust suppression

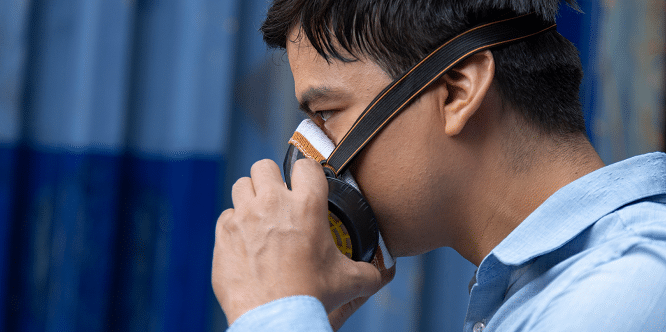

- PPE, such as respirators and face masks, to reduce inhalation

- Administrative controls to minimize dust emissions, such as regular air-quality monitoring,

- Occupational health surveillance programs

- Engineering controls such as exhaust ventilation systems help limit the amount of silica dust in the air.

- Regular monitoring and testing of airborne silica levels to identify high-exposure areas.

- Training workers on safe practices and raising awareness about the risks of silica exposure can help ensure everyone works together to minimize silica dust exposure.

You May Also Be Interested In…

- Do You Have Reasonable Suspicion?

Employers cannot initiate reasonable suspicion testing without first going through the 5-step process. Reasonable suspicion training provides critical information about how to initiate reasonable suspicion testing, including the 5-step process and other tools that employers can use to help manage the misuse of alcohol and drugs in the workplace.

Employers cannot initiate reasonable suspicion testing without first going through the 5-step process. Reasonable suspicion training provides critical information about how to initiate reasonable suspicion testing, including the 5-step process and other tools that employers can use to help manage the misuse of alcohol and drugs in the workplace. - An Employer’s Guide: What You and Your Employees Need to Know About DOT Drug & Alcohol Testing

When implementing or maintaining DOT Drug & Alcohol testing, there are key areas that employers should consider.

When implementing or maintaining DOT Drug & Alcohol testing, there are key areas that employers should consider. - SureHire Occupational Testing Acquires COHR Health: A Positive Step Towards Safe, Healthy, Productive Workforces and Communities

We are thrilled to announce that today, May 6, 2024, SureHire Occupational Testing has officially acquired COHR Health, a well-known leader in occupational health services. Read on…

We are thrilled to announce that today, May 6, 2024, SureHire Occupational Testing has officially acquired COHR Health, a well-known leader in occupational health services. Read on… - Occupational Testing Use Case – Mining

In this case study, we will explore how mining companies can use various types of occupational tests to reduce Total Recordable Incident Rates (TRIR) long term.

In this case study, we will explore how mining companies can use various types of occupational tests to reduce Total Recordable Incident Rates (TRIR) long term. - 9 Strategies to Keep Workers Cool on Drilling Sites During Hot Summer Months

This article delves into strategies to keep workers cool and safe on drilling sites during the hot summer months.

This article delves into strategies to keep workers cool and safe on drilling sites during the hot summer months. - Hearing Conservation Basics: How to Manage Occupational Noise

Learn how to proactively mitigate occupational noise risks and help prevent NIHL among workers.

Learn how to proactively mitigate occupational noise risks and help prevent NIHL among workers.